Case Study 6

Case Study 6

Lubemaster Cleans Gear Oil in Dump Trucks.

Lubemaster Cleans Gear Oil in CAT 793 Dump Truck

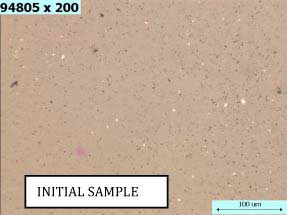

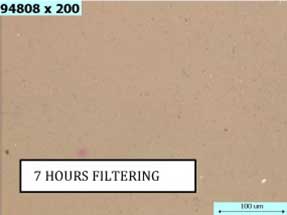

A German Creek Coal mine tested and trialled the Lubemaster OS600 fitted with a 5um final filter to provide assured cleanliness, for cleaning gear oil on a CAT 793 dump truck differentials. The dump truck diffs hold 800 litres of gear oil and CAT specs were met 3 hours after commencement of cleaning. Continuous circulation within the differential produced a washing effect, flushing contaminants from within the compartment.

Customer Feedback After Trial Completed

“G’day Fellas

The oil sample results for the modified filter cart trial on RD538 that was carried out on 16/09/2008 have arrived from the lab. In summary, the objective to achieve the recommended 18/15 ISO count (Caterpillar recommendation) was achieved and exceeded. Results are as follows;

Commenced at 10.00 AM, centrifuge only, three way valve switched to bypass filter, oil temperature at 64 deg C.

| TIME | SAMPLE | RESULT | OIL TEMP |

| 10.10 AM | Sample #1 | 20/15 | 63 deg C |

| 10.30 AM | Sample #2 | 20/13 | 63 deg C |

| 10.55 AM | Three way valve moved to allow oil flow though 5 micron filter element. | ||

| 11.00 AM | Sample #3 | 19/12 | 64 deg C |

| 11.30 AM | Sample #4 | 16/11 | 64 deg C |

| 12.00 PM | Sample #5 | 16/11 | 63 deg C |

| 1.00 PM | Sample #6 | 16/11 | 63 deg C |

| 2.00 PM | Sample #7 | 16/11 | 62 deg C |

| 3.00 PM | Sample #8 | 18/14 | 62 deg C |

| 3.55 PM | Sample #9 | 16/11 | 61 deg C |

End trial at 1600 hrs. Total filtering time = 6 hours.

In summary, the modified cart performed well. The inclusion of the larger capacity filter element made a drastic improvement in oil clean up time. The target level was achieved after only 90 minutes of operation.”

Regards

Condition Monitoring Technician